How it works

The dosing device is the heart of the sanding system. It is responsible for conveying the sand from the hopper into the distribution pipe. There are various methods for this, from pneumatic dosing methods to electric configurations. The sand is fed, either pneumatically or electrically controlled, from the sand container into the dosing device, where it is accelerated using compressed air and fed through an injector into the distribution pipe.

Types

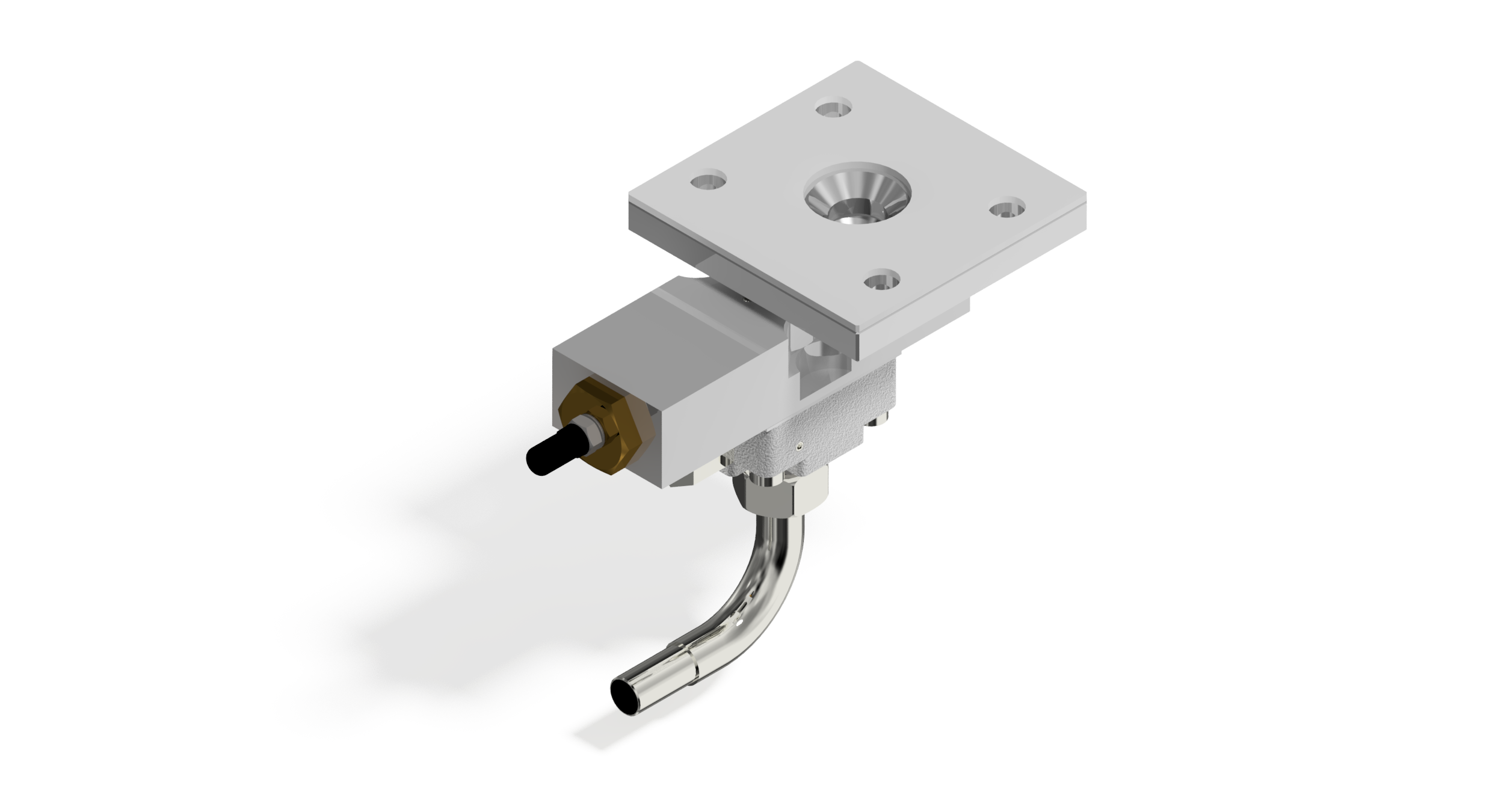

The P15 is a pneumatically actuated piston dosing unit for precise and stepless dosing of sand and for securely closing the sand container to the environment. It has been specially designed for quick and easy integration into vehicles. This feature is particularly important when retrofitting existing vehicles in order to make the sanding system compatible with current standards (TSI, GMRT2461, B011).

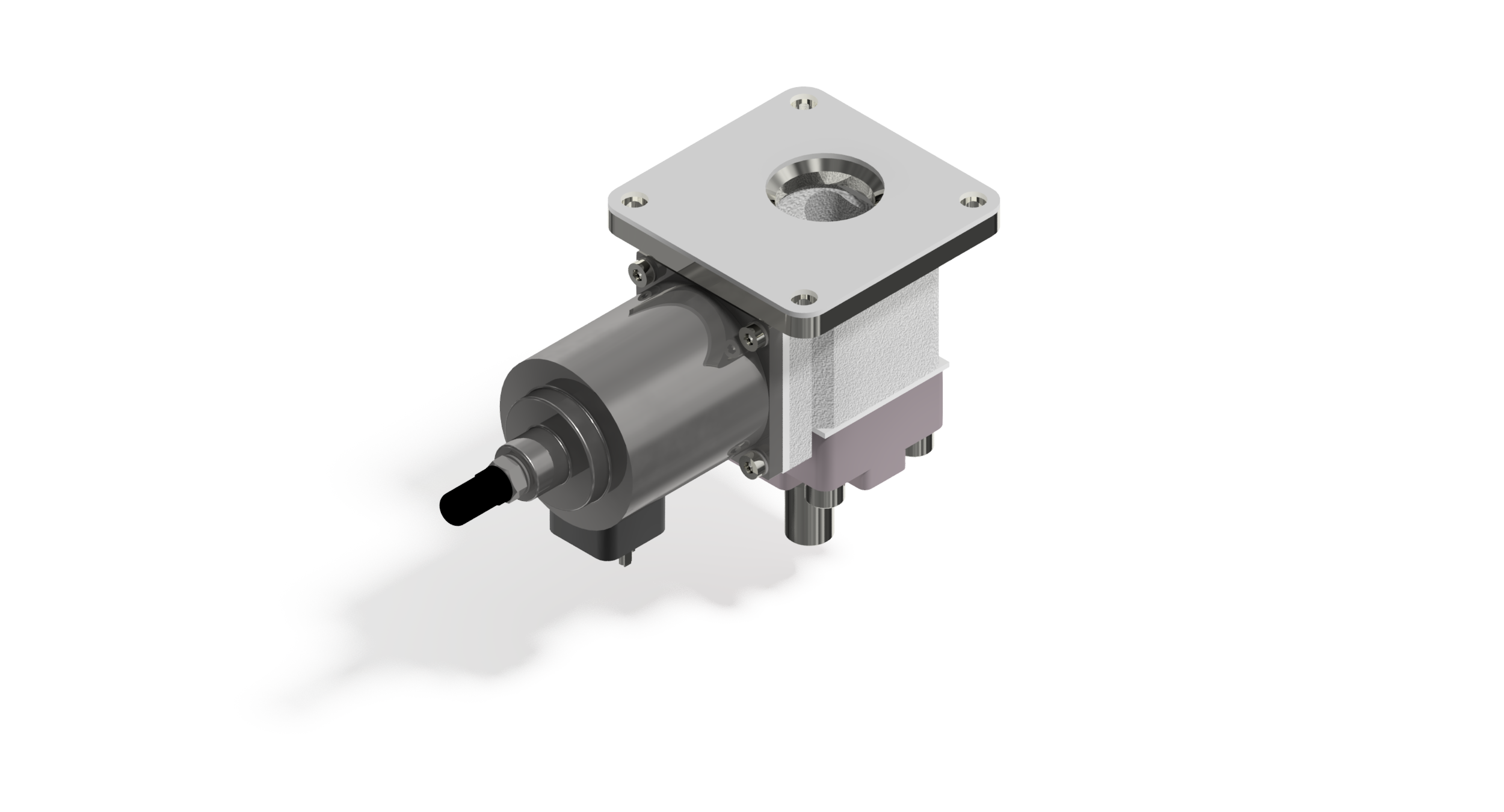

The ECON dosing device is a solenoid-operated piston dosing unit and, like all piston dosing units, can be infinitely adjusted. It ensures that the sand container is securely sealed off from the environment. A piston is pulled back by the solenoid and thus opens the sand flow into the dosing housing. A spring returns the piston to its original position.

The N45 is a solenoid-operated piston dosing unit and works on a similar principle to the ECON. Here too, precise and infinitely variable adjustment of the sand is possible and the sand container can be securely closed via the piston. Due to the fact that the solenoid is in the sand container, it has a smaller installation space and is better protected against external influences.

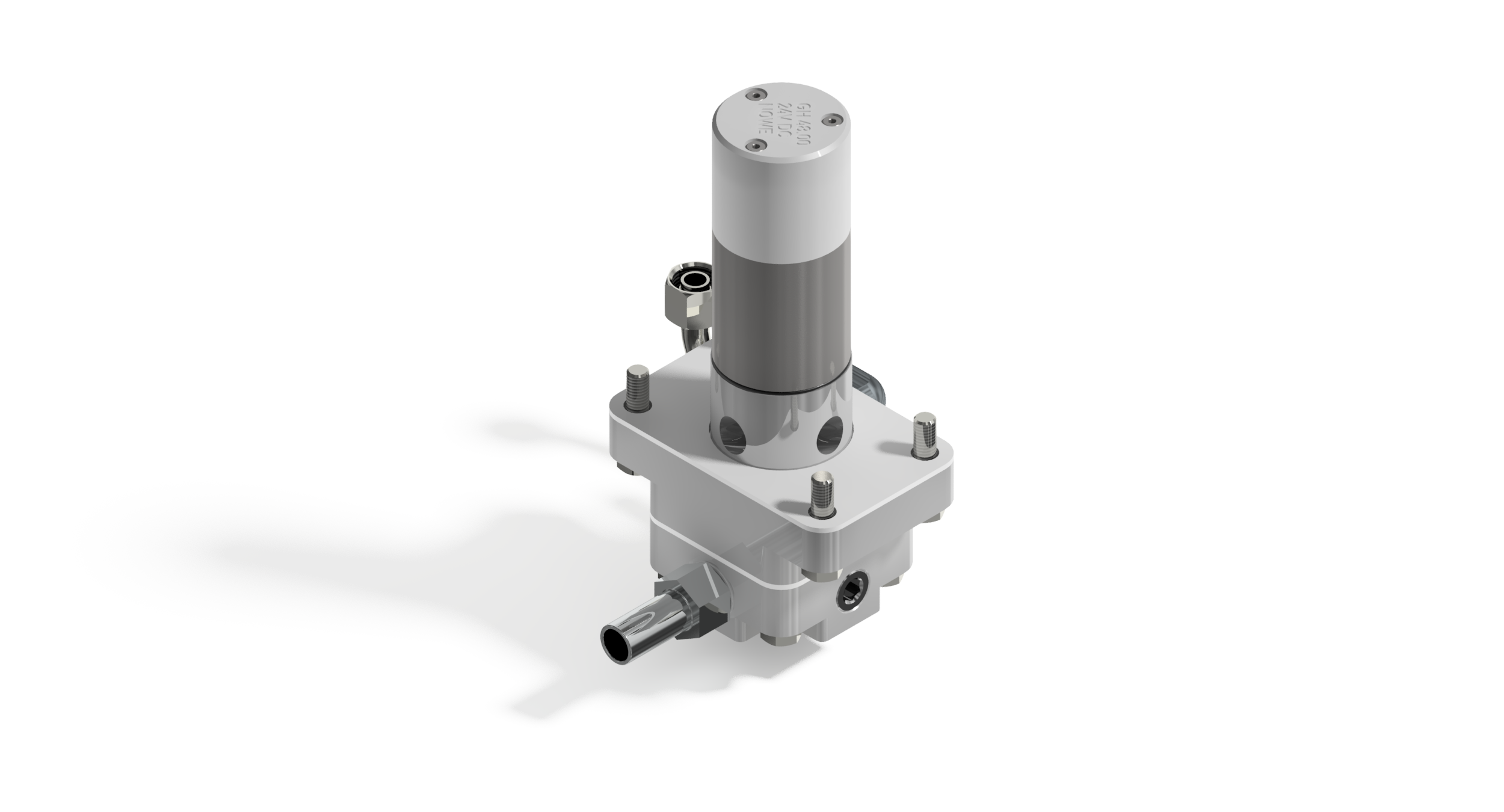

The Z30 is an electrically driven rotary feeder for conveying sand. The cellular wheel is rotated by an electric motor and thus conveys the sand in a fixed geometry. This allows it to be adjusted very precisely via the motor speed. Since at least four teeth of the cellular wheel are always in contact with the housing, a secure seal to the environment is also guaranteed here.

Information request

You can request detailed information using the following contact form.