Why sand at all?

In order for the train to start rolling or stop, it must transfer the force from the wheel to the rail. The force is transferred on the basis of the frictional force available in the wheel-rail contact, which depends on the coefficient of friction. Power transmission is possible in normal driving operation under dry conditions. However, if the surface is dirty or damp, the coefficient of static friction can drop too much, which reduces the frictional force. Safe, predictable operation can therefore no longer be guaranteed. Slipping or blocking of the wheel is not only a safety risk, but also increases wear on the wheel and rail. Our sanding systems build on this. They use sand to increase the coefficient of friction in the wheel/rail gap and thus ensure continuous power transmission. This not only increases general operational safety, but can also save high maintenance costs in some cases.

From the container to the rail

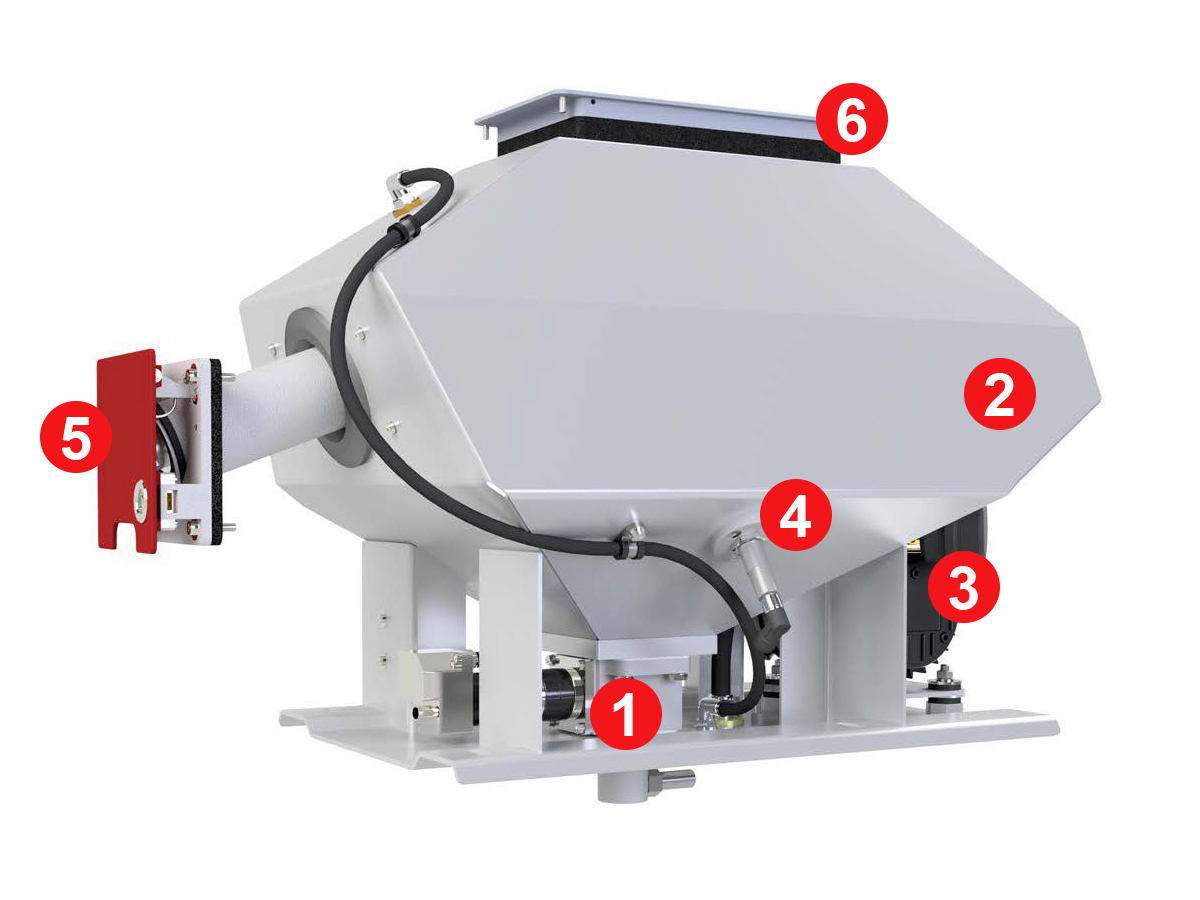

This is the basic idea. To create a simple and automated process for this, all components of the sanding system must work together. The sand container is the largest component of our systems. It is used to store the sand for the sanding processes and protects it from external influences and contamination. From there, the sand is fed into the dosing housing using one of the various dosing methods. Compressed air is fed into the dosing housing with the aid of the compressor and accelerates the sand. The accelerated sand is then fed through an injector into the spreader tube and from there into the wheel/rail gap.

Components

The dosing device accelerates the sand from the sand container in the dosing housing with compressed air from the compressor and then transports it through an injector into the spreader tube. It also has the task of protecting the inside of the grit container from environmental influences such as splash water or dirt.

The sand for sanding is stored in the sand container, protecting it from external influences.

The compressor supplies the pressure required for sanding in order to accelerate the sand in the dosing process.

Using the sand level sensor, the train driver can recognize in the cockpit when the sand level has fallen below a critical limit.

The outer filling flap is connected to the container via a pipe so that the sand container can be filled directly from the railroad track. These are lockable to prevent unauthorized “filling attempts”.

In order to be able to refill the sand from the inside, there is the option of an inside filling flap. Similar to the filling flap for the outside, they are also lockable.

Information request

You can request detailed information using the following contact form.